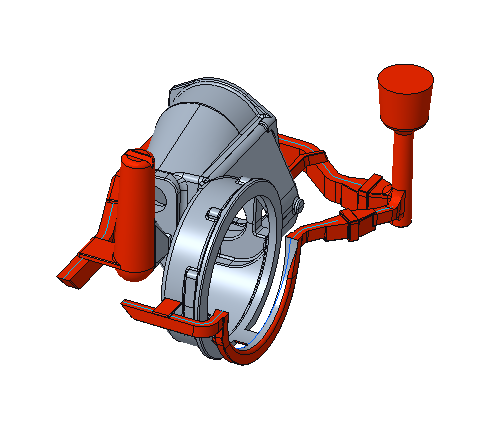

Step 1

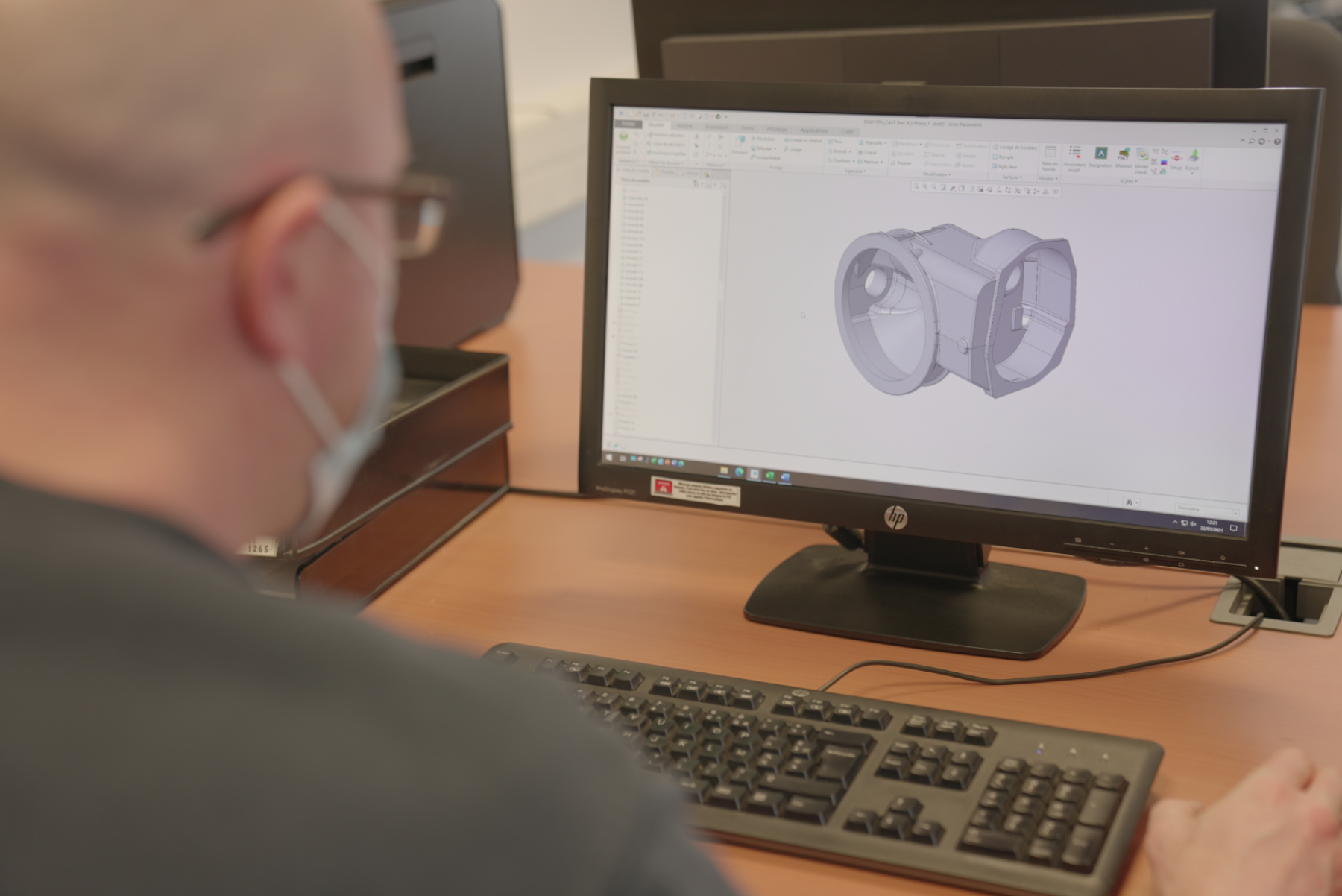

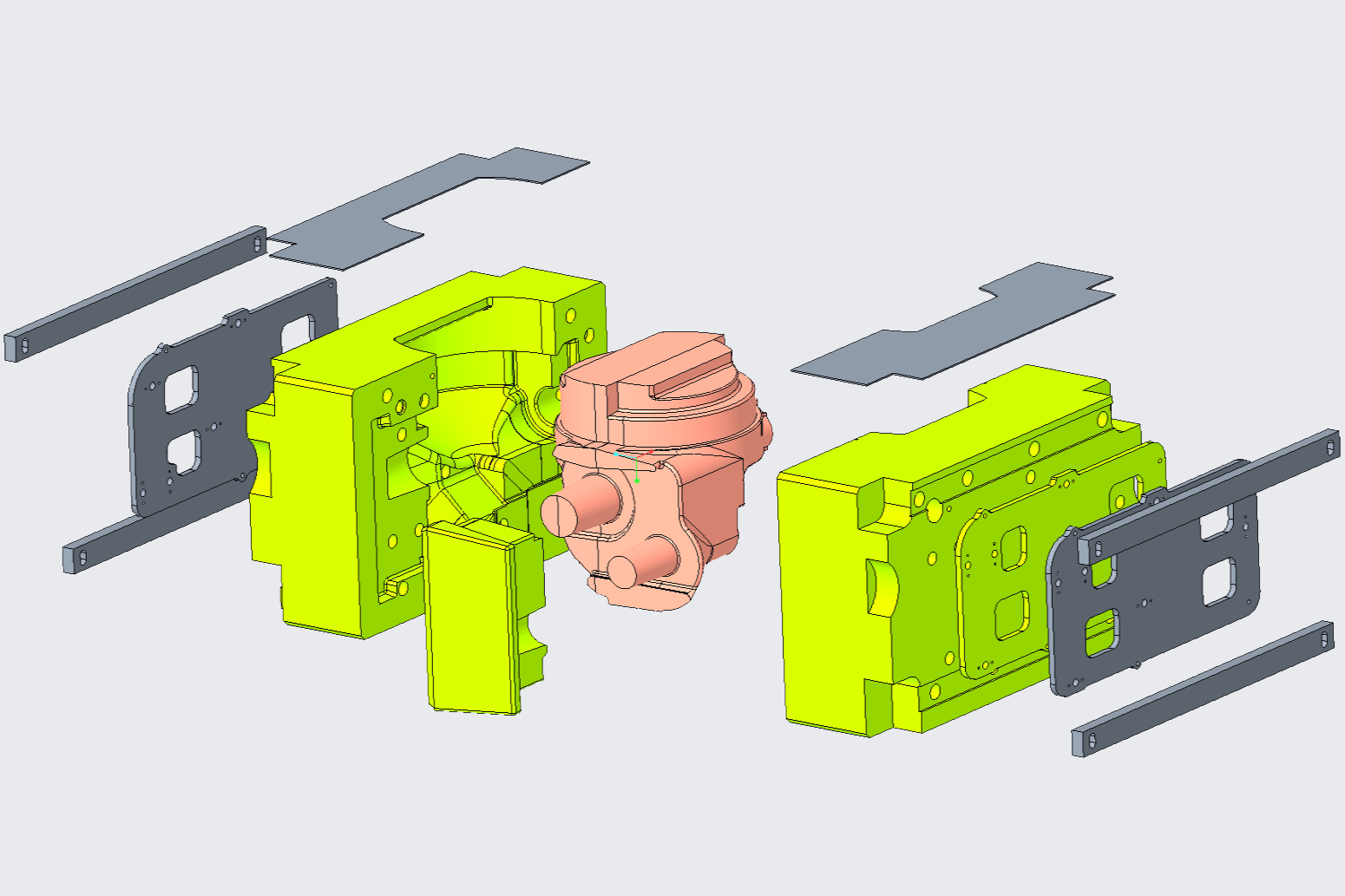

Creating CAD + CREO drawings.

Step 2

Adding drawing details (withdrawal, split line, draft, core, allowances, filling and feed system).

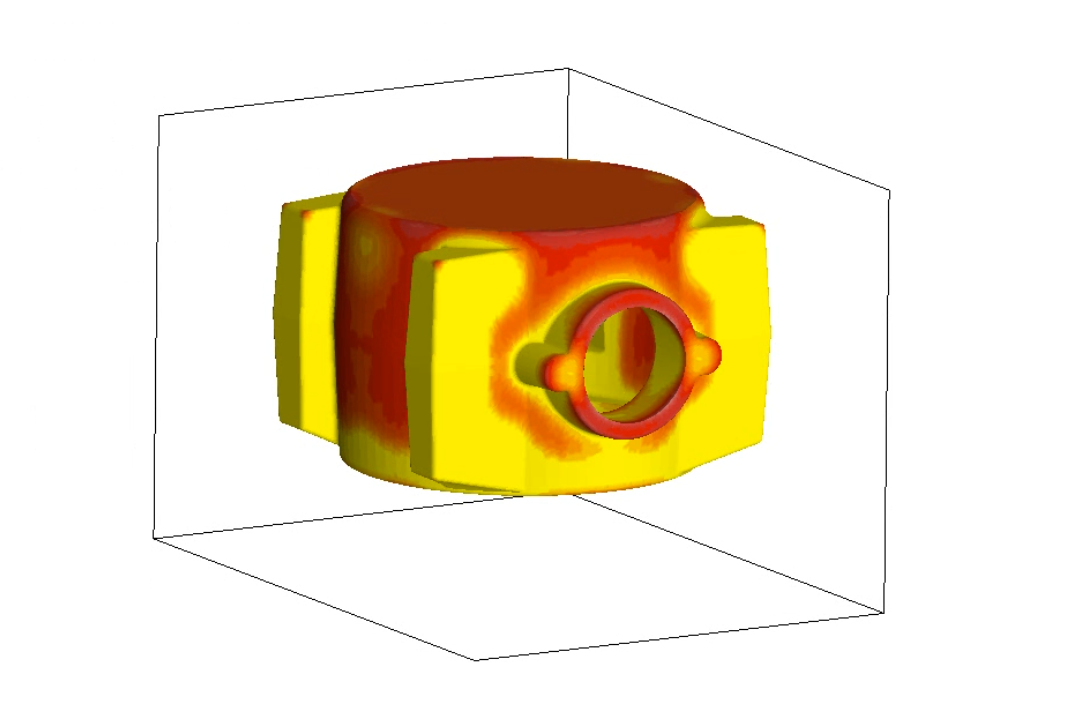

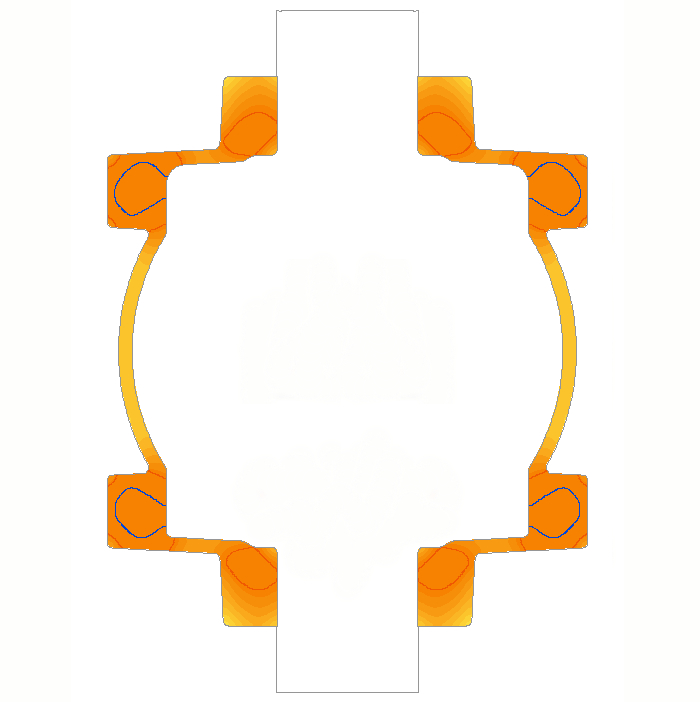

Step 3

Solidification simulation to identify possible defects. (NOVACAST)

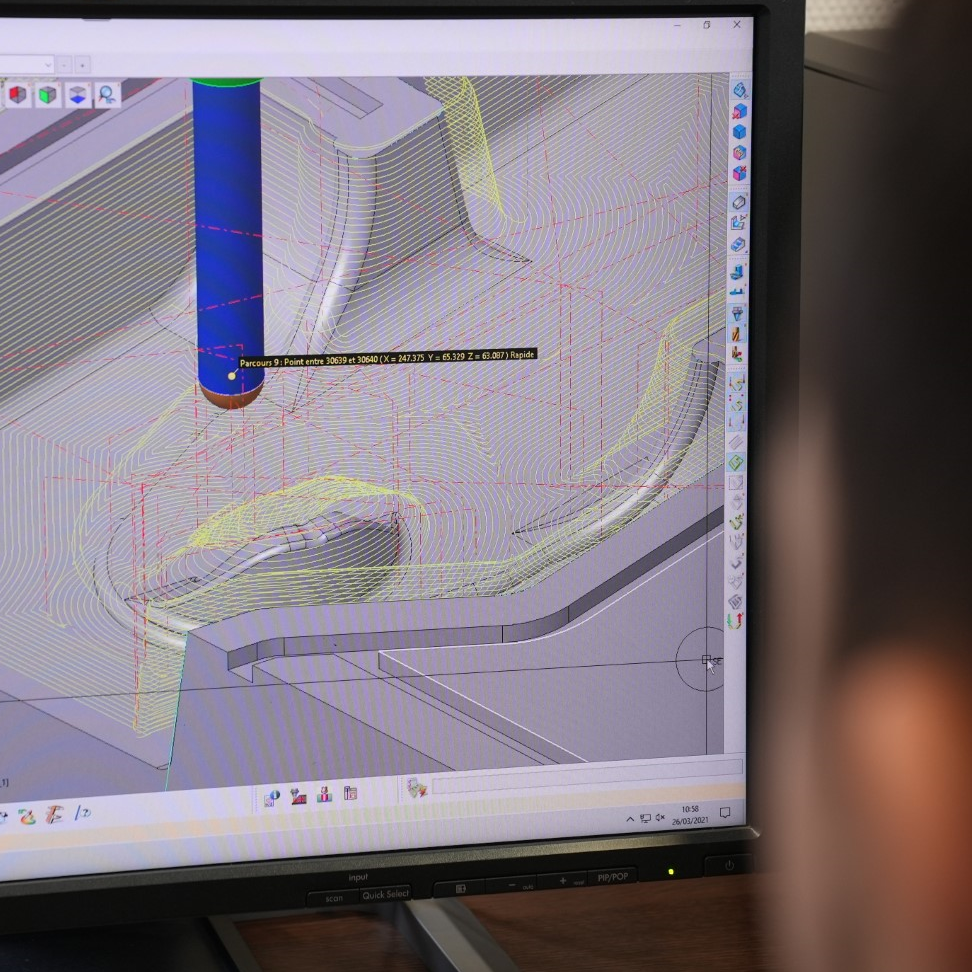

Step 4

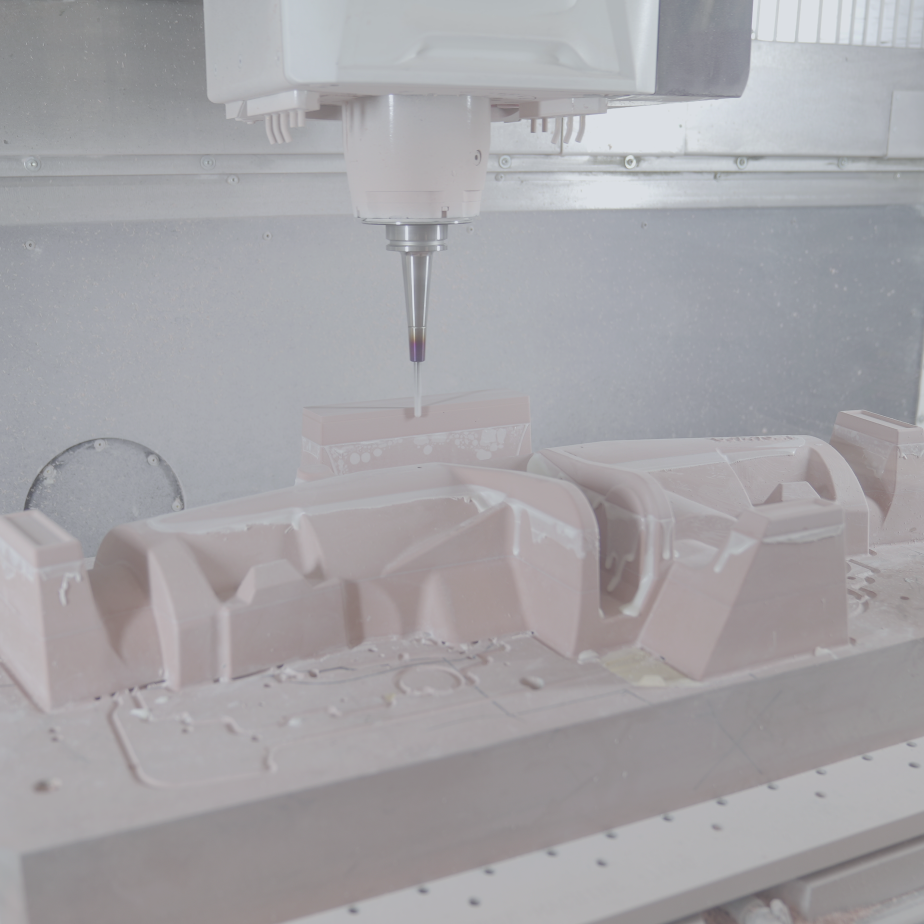

Transformation of CAM values into toolpaths by WorkNC machining software.

Step 5

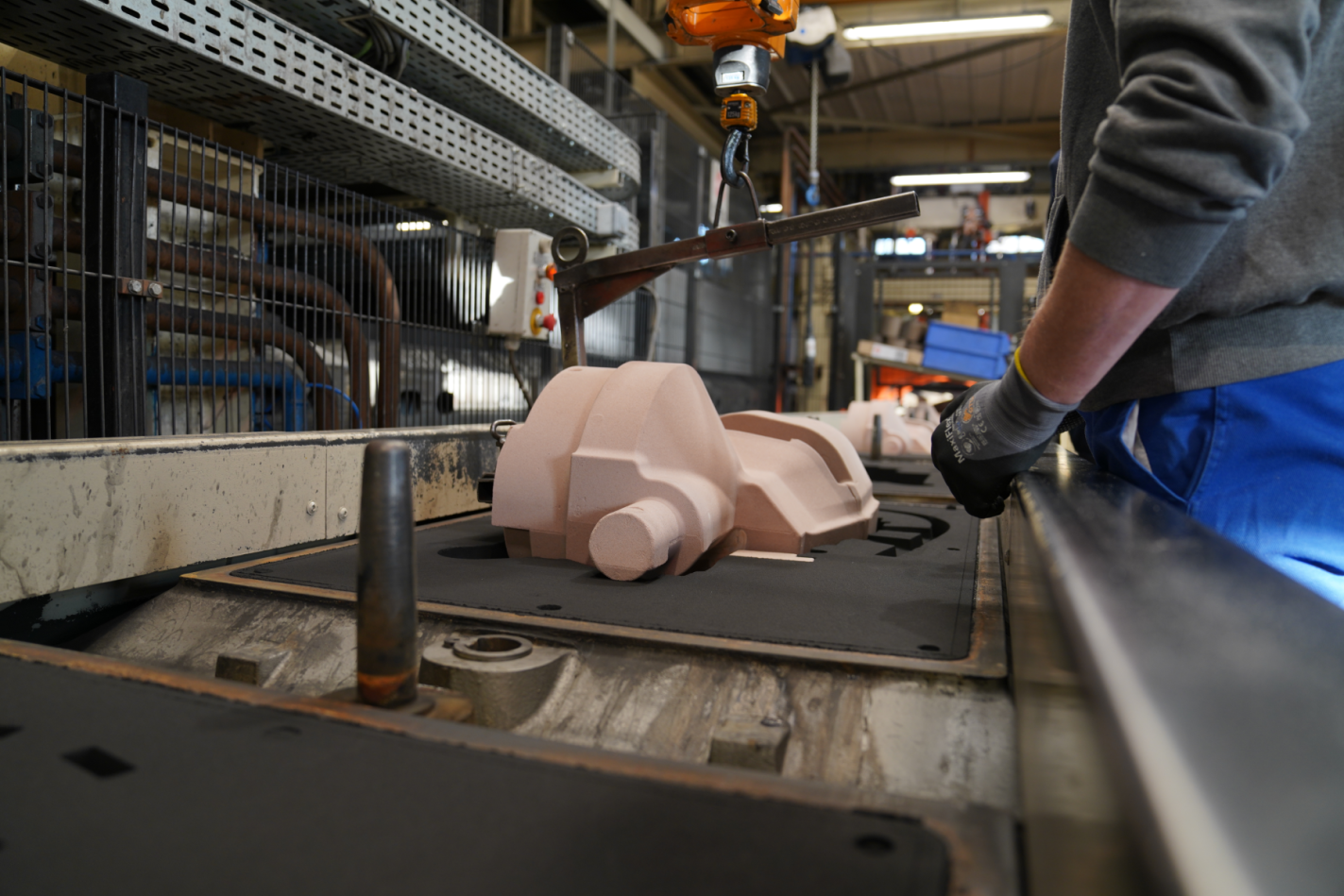

High speed tool machining. Modelling and pattern plate forming: injected polyurethane pattern plate.

Step 6

Integration of the machined model on a plate and addition of the devices allowing the casting of a part.

BETASET cold hardening process.

This stage of the manufacturing process is mainly necessary to produce hollow and/or complex shaped parts.The cores (ranging from 20 grammes to 150 kg) are produced on automatic multi-station machines manufactured by KUHN.

Moulding is carried out on 3 automatic installations:

- 1 fully automatic air impulse station with moulding box, 700 x 550 x 300/300

- 1 air flow press in moulding frames, 700 x 550 x 300/300

- 1 fully automatic high pressure installation with moulding box, 1100 x 700 x 330/330

The uniformity of our castings is guaranteed thanks to our electric melting process.

The flexibility of our facilities allows us to produce all grades of spheroidal and lamellar graphite cast iron in small and medium series, except for the "automotive" sector. Automatic parameter recording (temperature, chemical analysis of the alloy).

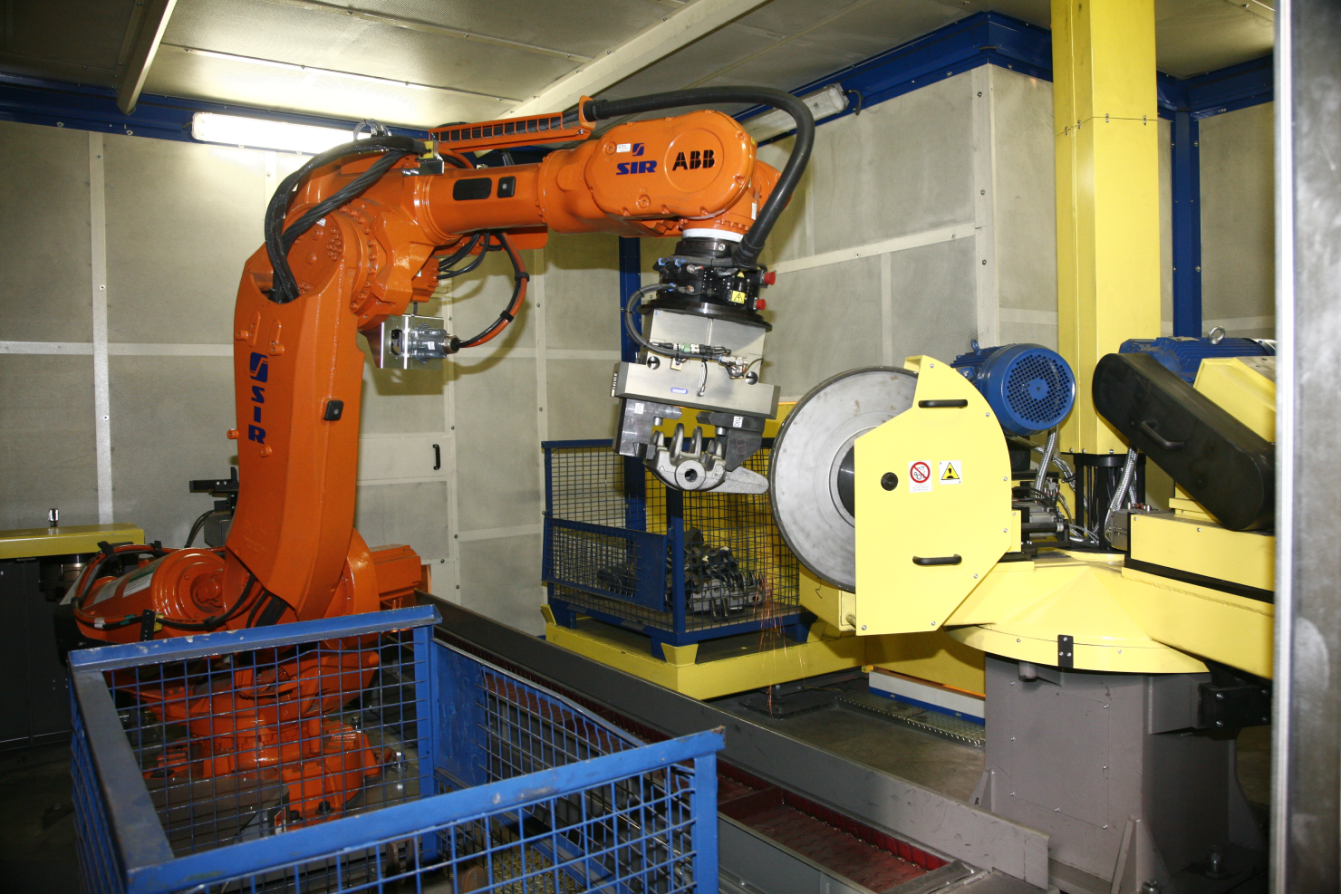

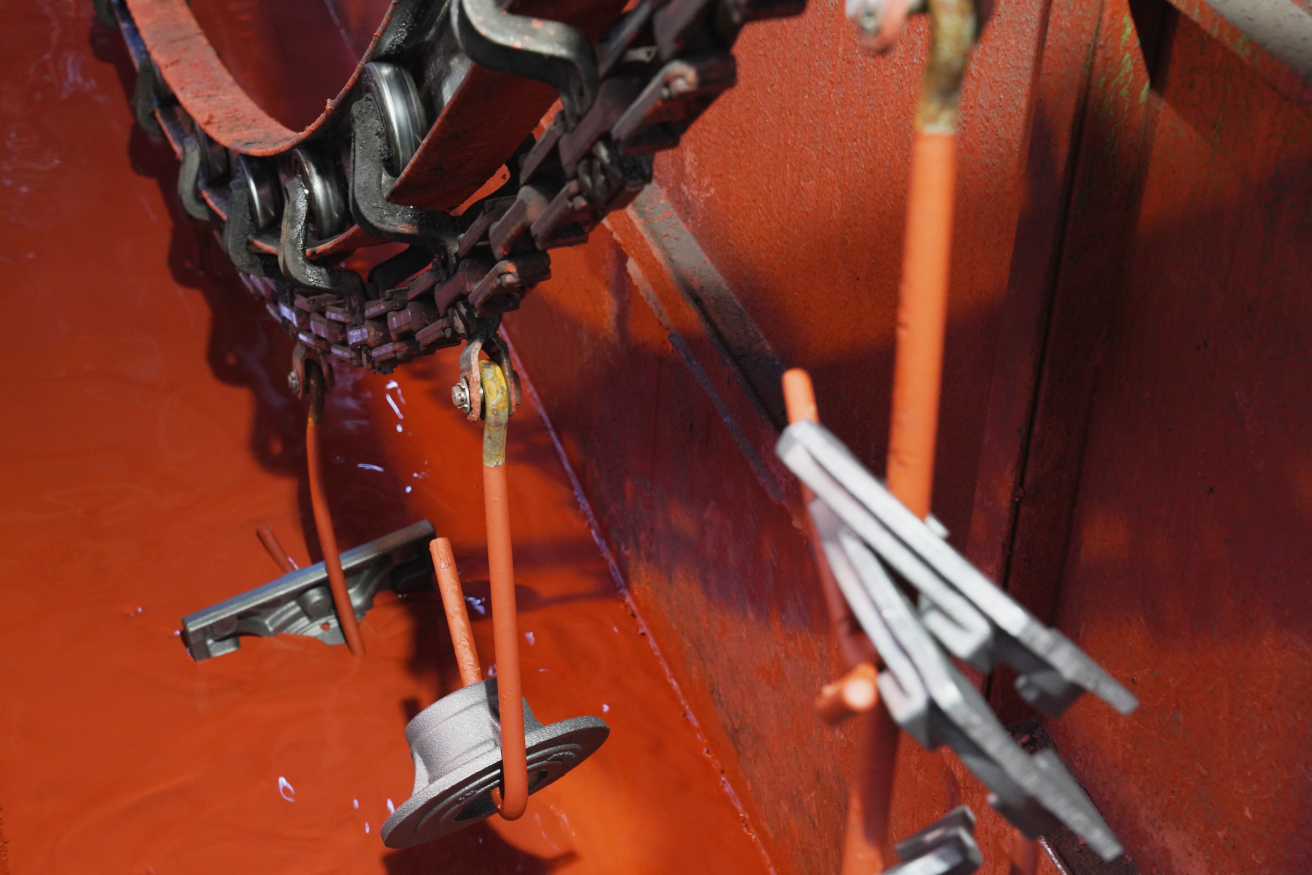

The shot blasting cleaning barrel is directly connected to the moulding shop. After being deburred on a CNC controlled grinding machine or a manual grinder, parts are painted in an automatic dip installation (hydrosoluble).